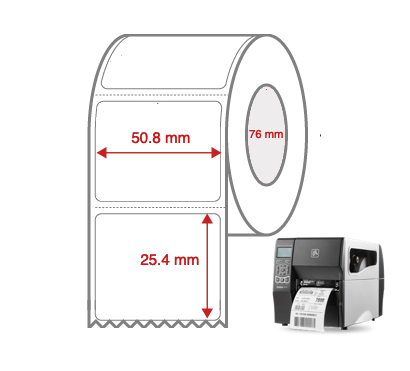

Direct Thermal Label Rolls 50.8mm x 25.4mm Perforated for Industrial Label Printers

High Quality Top Coated Direct Thermal labels made in Australia 50.8x25.4 for Industrial Label Printers

High Quality Top Coated Die Cut Direct Thermal Label Rolls with high performance adhesive.

Product Code and Description:

- SKU: 1001-20008 Direct Thermal Paper Permanent 76mm Core 4 Rolls of 5,000 = 20,000 Labels

- SKU: 1001-20009 Direct Thermal Paper Removable 76mm Core 4 Rolls of 5,000 = 20,000 Labels

- SKU: 1001-20010 Direct Thermal Synthetic Permanent 76mm Core 4 Rolls of 5,000 = 20,000 Labels

- SKU: 1001-20011 Direct Thermal Synthetic Permanent Freezer 76mm Core 4 Rolls of 5,000 = 20,000 Labels

Main Features:

- Label Size: 50.8mm Wide (Accross) x 25.4mm High/Long

- Labels Per Roll: 5,000

- Direct Thermal Material

- Ribbons are NOT required for Direct Thermal Printing

- Core Size, Material and Adhesive: Select from the drop down list

- Wound Out

- Die Cut, Blank

- 76mm Cores sizes are compatible with most industrial printer such as the Zebra ZT230, ZT410, ZT411, ZT621, ZT620, Honeyell PX65, PM45, SATO CL4NX, or via External Roll holder using a suitable desktop label printer

- Please Choose Carefully - Labels are NON Returnable and are custom made for each order

- Printer not included

- Manufacturing Lead Time - Standard Orders - 3 Business Days before shipping

- Manufacturing Lead Time - Larger Orders - 3-4 Business Days before shipping

Purchasing guide for selecting the correct labels:

Paper vs Synthetic Material:

The main difference between paper and synthetic materials for labels is their durability and resistance to environmental factors and that paper labels are more suitable for short-term labeling applications, while synthetic labels are better suited for long-term labeling needs, especially in harsh environments.

Paper labels are generally made from natural or recycled paper fibers, and are often used for short-term labeling applications. They can be printed on with various types of printing methods, including inkjet, laser, or thermal transfer printing. However, paper labels are typically more susceptible to moisture, sunlight, and temperature changes, which can cause them to degrade or become unreadable over time.

Synthetic labels, on the other hand, are made from durable materials like vinyl, polyester, or polypropylene. They are often used for long-term labeling applications and can withstand exposure to harsh environments, including extreme temperatures, sunlight, water, and chemicals. Synthetic labels are also resistant to tearing, smudging, and fading, making them ideal for use in industries such as manufacturing, logistics, and healthcare where labels need to be clearly visible and legible over extended periods of time.

Permanent vs Removable Adhesive:

The main difference between permanent and removable adhesives for labels is their strength and ability to be removed without damaging the surface.

Permanent adhesives are designed to create a strong, lasting bond between the label and the surface it is applied to. These adhesives are ideal for situations where the label needs to remain in place for an extended period of time, such as on product packaging, shipping boxes, or equipment. They are typically not designed to be easily removed, and attempting to do so may cause damage to the surface or leave adhesive residue behind.

Removable adhesives, on the other hand, are designed to create a temporary bond between the label and the surface. They are often used in situations where the label needs to be removed without damaging the surface, such as on rental equipment or promotional materials. Removable adhesives are typically less strong than permanent adhesives, but they still provide a secure hold while allowing for easy removal without leaving residue behind.

| Color | White |

|---|---|

| Label Width | 41 - 70mm |

| Label Height / Lenght | 1 - 25mm |

| Label Type: | Direct Thermal |