All you need to know about Thermal Transfer Ribbons

1. Why do I need a ribbon at all?

If you are printing thermal direct, you do not need a ribbon. In this case, the paper has a thermal coating that allows the print to show on the labels when the print head applies heat. However, this form of printing is limited and has longevity issues. It is similar to the process used to print thermal receipts from supermarkets.

If you want the print to last and look good for some time, you need to print thermal transfer (using a ribbon). Thermal transfer printing means that the print head applies heat to parts of the ribbon, melting the ink. The melted ink is then transferred to the label. This type of printing produces permanent prints that can be applied to a wide range of materials. It also lasts much longer than thermal direct labels.

2. What are the differences between Wax, Wax Resin and Resin ribbons?

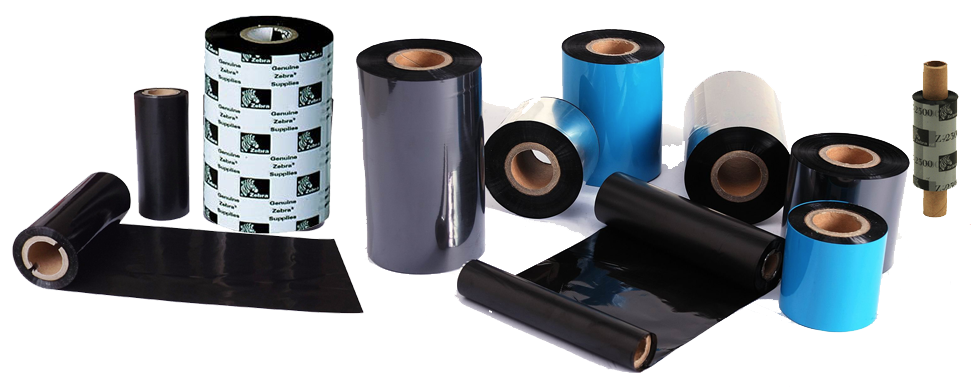

Wax ribbons are the cheapest type of ribbon. They are made almost entirely of wax, which is a soft material that scratches and smudges easily. wax ribbons are good for printing on labels with a rough surface.

Wax/resin ribbons are the most common type of ribbon that we sell. They are a combination of wax and resin, which is a harder material that provides more scratch and smudge resistance. Wax/resin ribbons can be used on most label materials.

Resin ribbons provide the best scratch and smudge resistance. However, they can be more difficult to print with than wax or wax/resin ribbons. The correct label material, printer heat, and speed settings are vital for a good result. Resin ribbons are often used for labels that need to be durable, such as asset labels, machinery labels, and labels that will be used outdoors.

What has head temperature and print speed got to do with the ribbon?

3. What has head temperature and print speed got to do with the ribbon?

The different types of ribbons (wax, wax/resin, and resin) need different head temperatures to melt the ink from the ribbon onto the label material. Even within the ribbon categories, some variation may occur. The speed that the label is being printed also has a direct impact on the quality of the print. If the printing speed is too high, the ink will not have time to get to the right temperature and the print will not turn out very well. Having the print head too hot can also have a detrimental effect on the print quality.

4. What size ribbon do I need?

To reduce print head wear, the ribbon should always be wider than the total label (and backing) width. Other considerations are the core size and the maximum outside diameter that your printer can take. If you are not sure, please let us know the label size and printer type so we can help you.

5. What is the difference between ribbons for near edge printers and flat head printers?

There are two common types of print heads in label printers: flat head and near edge. Flat head printers have heating elements located in the center of the print head, while near edge printers have print elements located closer to the trailing edge (hence the term “Near Edge”). The most common printer brands such as Zebra, Intermec, Datamax, and others are flathead printers. We can help you with your printer if you need to check what type it is.